Recent Projects

Implementation of Prediction Models for the City of Kansas City, Missouri

VTG, LLC and TransEducation Consulting, LLC teamed up to develop prediction models for the City of Kansas City Missouri to optimize Maintenance and Rehabilitation for its street system.

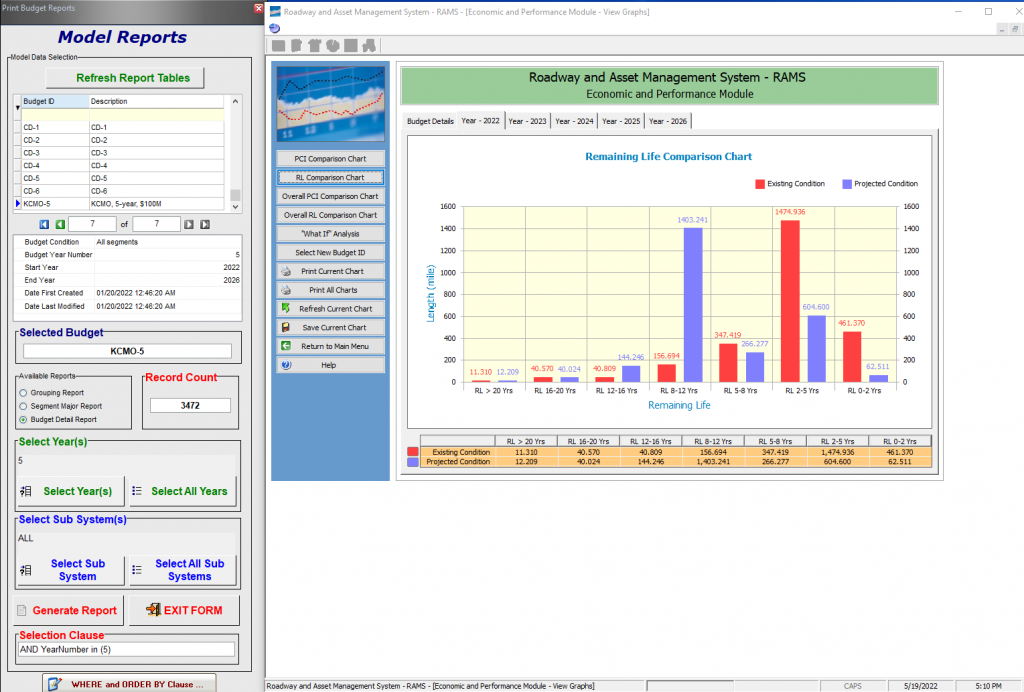

The prediction models were implemented as an extension to VTG’s existing Roadway and Asset Management System (RAMS).

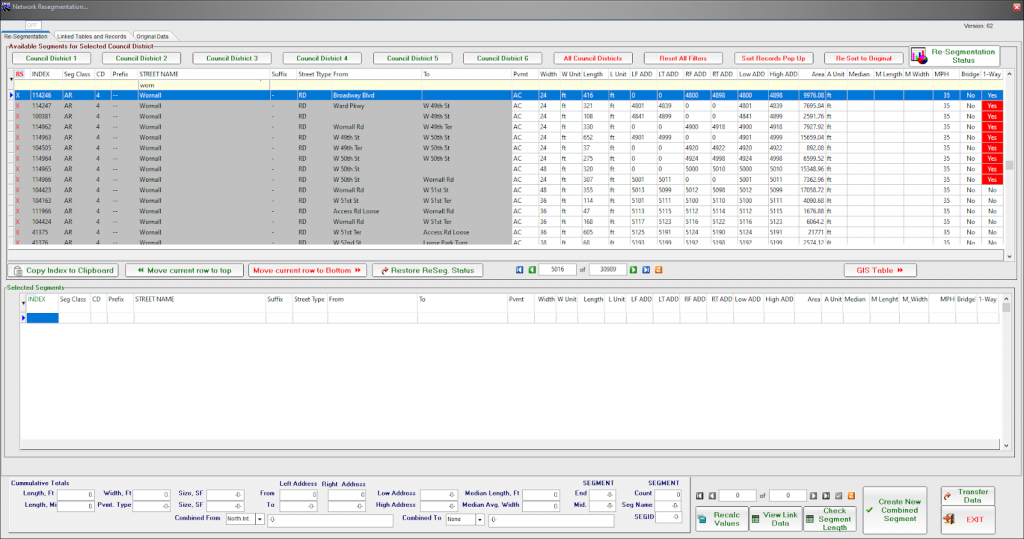

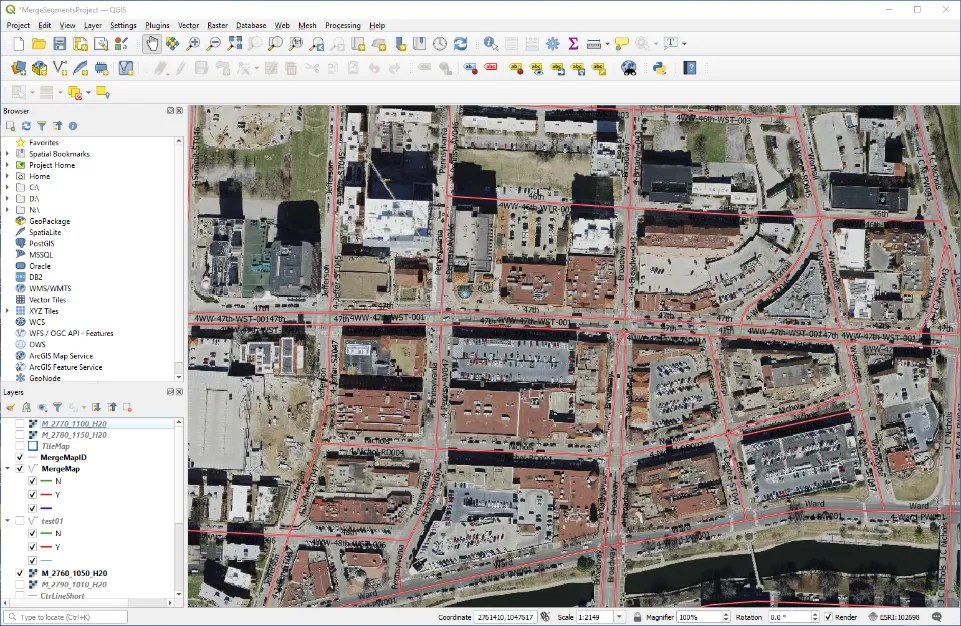

The project included the network re-segmentation of approximately 33,000+ segments comprising 2,500 miles. of road and streets. The resulting network was reduced to a more manageable 10,000+ segments or one third of the original number. A custom application was developed to merge existing segment using database form as well as an application for real time graphic display using a Geographic Information System (GIS ).

Re-segmentation Application

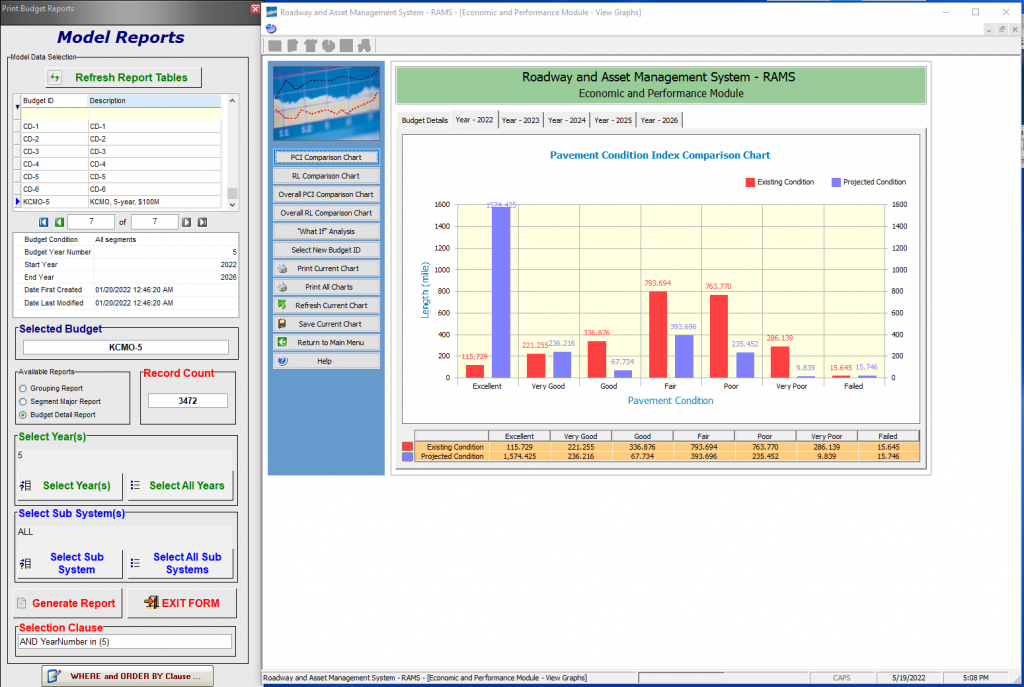

The model can be run for period of 1-8 years and also for selective portion of the network such an specific City Council District. The results can be displayed as graphs or comprehensive reports in user selected formats.

Project Pavement Condition Index, PCI

Projected Remaining Life, RL

For more details go to the RAMS page < link to RAMS page.

Evaluation of Landing Sites for Crew Space Transport Capsule

The Valencia Technology Group, LLC of Olathe, Kansas was selected by Boeing Corporation to do the evaluation of landing sites for the new Crew Space Transportation, CST-100. Boeing is developing the Commercial Crew Transportation System (CCTS) in partnership with NASA’s Commercial Crew Program which aims to resume U.S.-based flights to space by 2017. It will replace the retired Space Shuttle as the primary space transport.

As part of this project VTG personnel completed geological and engineering assessments of potential sites in California, Utah, New Mexico and Arizona. Our team is without a doubt the most qualified and experienced team in the country in this type of work.

Members of the team included Dr. David Kraft, former Dean of the Schools of Engineering at the University of Dayton and Kansas and nationally known Geotechnical and pavements consultant and Mr. Gary Kratochvil, a geologist with extensive experience in landing sites evaluation and former Science Advisor to the Astronauts at NASA. Javier Valencia, VTG’s President, was the Lead Engineer and Project Manager. His areas of expertise include engineering assessment of unsurfaced landing surfaces for high performance aircraft as well as the design and construction of custom testing, data acquisition and information management systems such as the one used to certify the landing surfaces for the Space Shuttle prior to landing and for which he was solely responsible from the late 80s until the end of the program. Altogether, the principal members of the team have close to 100 years of combined experience in this type of work.

The work included advanced analysis of satellite imagery as well as field inspections using conventional methods as well as a new approach that included the use of and advanced Small Unmanned Aircraft Systems (sUAS) more commonly known as drones to obtain high-definition photography to supplement the aerial and satellite imagery as well as geocoded videography.

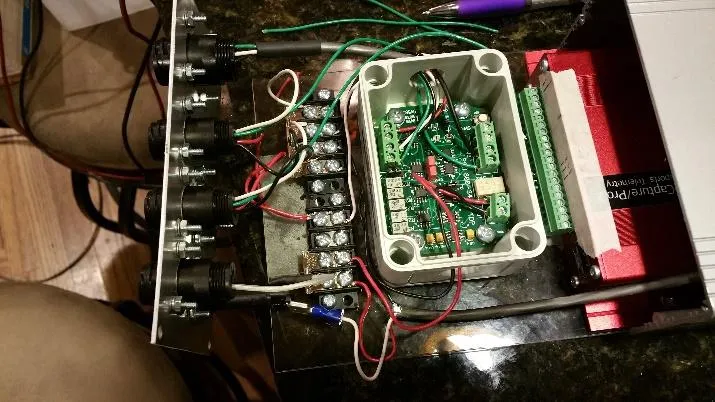

As part of the project VTG also designed and fabricated a trailer mounted test rig to evaluate the air bags used by the space capsule at landing. The data acquisition portion used advanced technology to incorporate real time GPS position as well as a data collection system similar to the one used by high performance race cars, including real time telemetry.

We are very excited to be part of such prestigious project that will help our country regain the lead in space exploration and continue our participation in the space program.

For more information on the new Boeing CTS-100 Capsule you can go to:

Boeing: Starliner CST-100 Reusable Spacecraft Capsule

VTG completed of the evaluation of the four candidate landing sites for the new space capsule and delivered the drag friction test trailer designed and built to Boeing specifications to test the air bags that will support the capsule during landing. A final report was prepared and submitted including both the engineering and geological evaluations of the candidate sites as well as recommendations.

The report includes analysis of data captured from satellite imagery, site visits, on site testing and imagery captured on site by our high performance Small Unmanned Aircraft System (sUAS) more commonly referred to as drone.

The field testing consisted of engineering and geological evaluations of soils including classification, chemical composition, and strength. Samples were also collected for laboratory testing.

The drag friction test trailer was delivered to Boeing at the White Sands site where it was tested under various conditions. The trailer was then used at all the candidate sites as well as the Langley facility where the preliminary testing of the Capsule with air bags took place.